Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

Cargo ships play a vital role in global trade, but how fast do they actually go? For businesses and logistics managers, understanding cargo ship speed is key to optimizing shipping and reducing costs. In this article, we will explore the factors influencing cargo ship speed, focusing on technologies like the pitch propeller. You will learn how these technologies help enhance efficiency, reduce fuel consumption, and improve delivery timelines.

Cargo ships come in various sizes, and their speed is often determined by their type and design. The size of the ship is directly related to the weight of the cargo it carries, and larger ships tend to travel slower due to the increased drag caused by their size and weight.Larger ships generally travel slower due to their size and the weight of the cargo they carry. For instance, bulk carriers are designed to transport large quantities of raw materials, making them slower but more stable. In contrast, container ships prioritize speed to ensure quick turnaround times for goods transport. The larger the ship, the more power it requires to maintain speed, which ultimately impacts its ability to achieve high cruising speeds.The speed of cargo ships varies depending on their type. Container ships typically cruise between 20-25 knots, while bulk carriers and oil tankers generally range from 12-16 knots. The size and weight of the ship are key factors in this variation. Container ships need to prioritize speed to keep up with fast schedules, while bulk carriers are designed for slow, steady travel, focused more on capacity than speed.

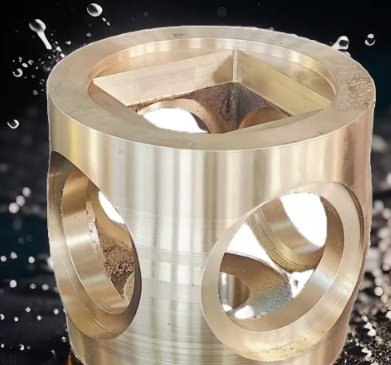

One of the most important components influencing a ship's speed is its propulsion system. The introduction of the pitch propeller has revolutionized the maritime industry by allowing ships to adjust their speed and fuel consumption more efficiently, offering significant advantages in terms of fuel economy and operational flexibility.The pitch propeller works by adjusting the angle of the blades, which controls the amount of thrust generated by the engine. This helps maintain a steady speed, especially when encountering rough weather or strong currents. The ability to adjust the pitch allows ships to optimize fuel consumption, improving overall efficiency and speed control. When weather conditions change or ocean currents are strong, the pitch propeller can adapt the blade angle to maintain optimal performance.

Unlike traditional propulsion systems, which use fixed blades, pitch propellers provide greater flexibility. This makes them more efficient for controlling a ship’s speed, particularly when dealing with changing conditions such as ocean currents or stormy weather. Traditional fixed-blade systems can only provide a constant level of thrust, regardless of external conditions, making pitch propellers far more effective at maintaining speed without overloading the engine.

The speed of a cargo ship is also affected by environmental factors such as ocean currents, weather, and the shipping route. These factors can either speed up or slow down a vessel's journey.Favorable ocean currents can speed up a ship’s journey, while adverse weather conditions such as high winds and storms can slow it down. Additionally, a ship traveling against ocean currents will require more power to maintain speed. While some ships are equipped to handle rough conditions, prolonged adverse weather will slow progress and increase fuel consumption.

A ship’s route significantly impacts its speed. Routes through open waters tend to allow for faster cruising, whereas constrained waterways like canals and busy ports slow the ship’s pace. Navigating narrow shipping lanes, avoiding obstacles, or waiting in congested ports all reduce a vessel’s efficiency. Route planning that accounts for these factors can help optimize travel time, ensuring more predictable delivery schedules.

Container ships are designed to maximize speed and efficiency, which is crucial for maintaining tight schedules and fast turnaround times for goods.

● Speed: These vessels typically travel at speeds between 20-25 knots, balancing the need for speed with the efficiency required for large-scale cargo transport. As container ships carry standard-sized containers, they are designed to move large amounts of goods quickly while reducing dock times.

● Efficiency Considerations: While container ships are faster, they are designed to optimize both speed and cargo handling, ensuring the efficient movement of goods between ports while minimizing fuel consumption. These ships are equipped with systems that allow for quick loading and unloading, maintaining speed while ensuring efficiency.

Bulk carriers are designed for transporting large quantities of loose cargo such as coal, grain, and iron ore. As such, they prioritize load capacity over speed.

● Speed Range: Bulk carriers generally travel between 12-16 knots. Their design is focused on efficiency in carrying large amounts of cargo rather than speed. The slower speeds are offset by their ability to carry massive loads at a reduced cost.

● Design and Purpose: The slower speeds of bulk carriers are a trade-off for their ability to transport massive quantities of raw materials, offering cost-effective shipping on longer journeys. The bulk carrier’s design emphasizes space and stability, making it ideal for moving goods that do not require fast delivery.

Oil tankers are large vessels used to transport liquid cargo, primarily crude oil and refined products. Their speed is secondary to safety and cargo management.

● Speed: Oil tankers typically cruise at speeds of 13-15 knots, with their design focusing on stability and efficient fuel consumption over speed. The slower speed helps maintain the tanker's balance, which is crucial when transporting liquid cargo.

● Design Focus: The design of oil tankers ensures safety and stability, as transporting liquid cargo requires careful handling to prevent spills and maintain balance during transit. The slower speed ensures greater stability and control, minimizing the risk of accidents or environmental damage.

Ship Type | Speed Range (Knots) | Design Focus | Typical Cargo |

Container Ships | 20-25 | Speed and efficiency | Standardized containers, time-sensitive cargo |

Bulk Carriers | 12-16 | Load capacity, stability | Loose cargo such as coal, grain, ores |

Oil Tankers | 13-15 | Stability and fuel efficiency | Liquid cargo like crude oil and refined products |

A bow thruster is a device installed at the bow (front) of a ship, designed to aid in lateral movement, making it easier to navigate tight spaces. By pushing water through a nozzle, bow thrusters provide additional thrust to move the ship sideways, facilitating maneuvering when docking or navigating narrow areas.While the bow thruster does not directly affect the ship's cruising speed, it plays an essential role in maintaining operational efficiency during docking and maneuvering in confined spaces. This enables the ship to maintain optimal speeds without being delayed by complex maneuvers.

Bow thrusters are particularly advantageous in situations requiring high maneuverability, such as docking in busy ports.Unlike traditional rudder-based systems, which primarily control a ship's direction, bow thrusters provide better control over lateral movements, allowing for faster and more efficient docking. This makes them ideal for large cargo vessels operating in crowded or constrained environments.

Propulsion System | Speed Control | Efficiency | Flexibility | Typical Use Case |

Pitch Propeller | Adjustable | Optimizes speed and fuel | High | Ships operating in varying weather or currents |

Fixed Blade Propeller | Fixed | Less efficient at varying conditions | Low | Older ships, steady conditions |

Slow steaming refers to reducing a ship’s speed to conserve fuel and lower emissions, a practice increasingly used by shipping companies. By reducing speed, ships use less fuel, which helps save costs and reduce environmental impact. While this results in longer travel times, the trade-off is often worth it for the savings in fuel costs. This practice helps shipping companies cut down on their overall operational expenses, especially when fuel costs are high.Slow steaming allows shipping companies to reduce their operational costs significantly, especially on long-haul routes. However, it comes at the cost of increased transit time. Although this method can extend delivery times, it provides substantial fuel savings and lower environmental impact.

To comply with some environmental regulations, many ships have had to reduce their speed to lower their emissions. While this ensures compliance with global environmental standards, it can lead to longer shipping times.Shipping companies must balance environmental compliance with the need for timely deliveries. Some new technologies, such as hybrid propulsion systems, allow for a better balance between speed and environmental friendliness, reducing the need for slow steaming while still minimizing emissions.

Understanding how to calculate shipping time is crucial for accurate logistics planning. Cargo ship speeds are measured in knots, where 1 knot equals 1.15 miles per hour or 1.85 kilometers per hour.You can calculate shipping times by knowing the distance between two ports (in nautical miles) and the ship’s speed (in knots). For example, if a cargo ship travels 240 nautical miles at 20 knots, it would take approximately 12 hours. When calculating shipping times, it's essential to account for real-world variables like weather, ocean currents, and port delays. These factors can cause variations in actual travel time, making it important for businesses to factor in contingencies when estimating shipping times.

The speed of cargo ships depends on factors like size, type, propulsion systems such as pitch propellers, and environmental conditions. Understanding these variables helps businesses optimize logistics, improve shipping times, and reduce costs. For those seeking high-quality propulsion solutions, ZHENJIANG JINYE PROPELLER CO.,LTD. offers advanced pitch propellers designed to enhance fuel efficiency and operational performance, providing excellent value for the maritime industry.

A: The speed of a cargo ship is determined by its size, type, propulsion system, and environmental factors like weather and currents. For example, ships with pitch propellers can adjust speed efficiently, optimizing fuel use.

A: A pitch propeller allows the ship to adjust the angle of the blades, improving speed control and fuel efficiency, especially in challenging conditions like strong currents or rough weather.

A: Container ships prioritize speed to meet fast schedules for transporting standardized containers, while bulk carriers focus on carrying large loads at slower speeds, typically between 12-16 knots.

A: Yes, adverse weather, like high winds or storms, can slow a cargo ship’s speed. Ships equipped with pitch propellers can adjust to these conditions more effectively to maintain consistent speed.

A: By adjusting the blade angle, pitch propellers optimize thrust, helping ships use fuel more efficiently and maintain the desired speed, reducing overall fuel consumption.

The Kongsberg Team visited Zhenjiang Jin Ye Propeller Co., Ltd. on September 11, 2025

Zhenjiang JinYe Propeller Co., Ltd. Shines at Marintec China 2025

What Is Needed for Steering Control on A Personal Watercraft

KONGSBERG MARITIME PROPULSION TEAM Visited Zhenjiang Jinye Propeller Co., Ltd. On April 10, 2025